NFPA 35, Standard for the Manufacture of Organic Coatings

Stay up to date on hazard protection in manufacturing facilities that handle organic coatings.

Learn about the latest in industrial hazard control with NFPA 35, Standard for the Manufacture of Organic Coatings. This standard’s requirements address facilities that manufacture organic chemical-based coatings, such as paints and inks for automotive, industrial, institutional, household, marine, printing, transportation, and other applications.

The chapters in NFPA 35 address the following:

- Material storage and handling

- Process equipment and operations

- Control of ignition sources

- Training and emergency planning

- Building construction

- Special hazards

- Inspections and maintenance

- Fire protection

NFPA 35 is essential for anyone involved with the design, construction, operation, safety, or maintenance of facilities that produce flammable and combustible organic coatings.

The 2026 edition features several updates, including:

- List of documents referenced throughout the standard has been updated.

- Extracts from NFPA 30 are now revised to the 2024 edition of that code.

- Water additive concentrates are now permitted to be used in automatic sprinkler systems within manufacturing and storage buildings.

Table of Contents

Chapter 1 Administration1.1 Scope.

1.2 Purpose.

1.3 Application. (Reserved)

1.4 Retroactivity.

1.5 Equivalency.

1.6 Units and Formulas.

1.7 Code Adoption Requirements. (Reserved)

Chapter 2 Referenced Publications2.1 General.

2.2 NFPA Publications.

2.3 Other Publications.

2.4 References for Extracts in Mandatory Sections.

Chapter 3 Definitions3.1 General.

3.2 NFPA Official Definitions.

3.3 General Definitions.

3.4 Classification of Liquids.

Chapter 4 Location of Plants and Buildings4.1 Location.

4.2 General Layout and Design.

Chapter 5 Building Construction5.1 General Construction.

5.2 Drainage.

5.3 Building Heating.

5.4 Ventilation.

5.5 Deflagration (Explosion) Venting.

5.6 Electrical Equipment.

Chapter 6 Process Equipment and Operations6.1 Transfer of Flammable and Combustible Liquids.

6.2 Piping, Valves, and Fittings.

6.3 Kettles, Reactors, and Vessels.

6.4 Dispersion Equipment.

6.5 Ball Mills and Pebble Mills.

6.6 Mixers and Mixing Tanks.

Chapter 7 Material Storage and Handling7.1 Tank Car and Tank Vehicle Unloading and Loading.

7.2 Flammable and Combustible Liquid Storage.

7.3 Storage of Finished Products.

7.4 Outdoor Storage.

7.5 In-Plant Transportation and Storage of Portable Shipping Tanks.

7.6 Power-Operated Industrial Trucks.

Chapter 8 Special Hazards8.1 Nitrocellulose.

8.2 Monomers.

8.3 Organic Peroxide Formulations.

Chapter 9 Control of Ignition Sources9.1 Ignition Sources.

9.2 Smoking.

9.3 Hot Work.

9.4 Repair of Electrical Equipment.

9.5 Static Electricity Hazards.

9.6 Lightning Protection.

Chapter 10 Management of Fire Hazards10.1 Scope.

10.2 Basic Requirements.

10.3 Evaluation of Hazards.

10.4 Emergency Action Plans.

10.5 Management of Change.

10.6 Fire Investigation.

Chapter 11 Fire Protection11.1 Scope.

11.2 Automatic Sprinkler Protection.

11.3 Fire Hydrants.

11.4 Emergency Notification.

11.5 Portable Fire Extinguishers.

11.6 Standpipe and Hose Systems.

11.7 Hose Connections.

11.8 Fixed Local Application Extinguishing Systems.

Chapter 12 Training and Emergency Planning12.1 Basic Training Requirements.

12.2 Emergency Planning.

Chapter 13 Inspection and Maintenance13.1 General.

13.2 Confined Space Entry.

13.3 Cleaning Tanks and Vessels.

13.4 Floor Cleaning.

Annex A Explanatory Material

Annex B Operational Practices

Annex C Informational References

2026 (9781455932351)

2021 (9781455927340)

2016 (9781455912971)

2011 (NFPA35-11)

| Price | $219.95 |

|---|---|

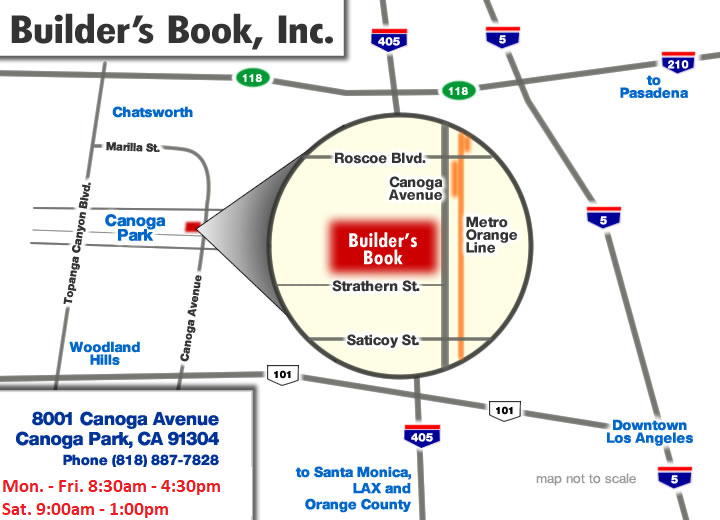

| Customer Service | We're Here To Help! Call us anytime during our customer service hours... Monday through Friday - 8:30 am to 4:30 pm (Pacific) Order Questions:

TOLL FREE, 800-273-7375 (Outside the U.S. call 818-887-7828). Our Address: 8001 Canoga Avenue Canoga Park, CA 91304 US Phone: 800-275-2665 E-mail: sales@buildersbook.com

|

| Description | Stay up to date on hazard protection in manufacturing facilities that handle organic coatings. Learn about the latest in industrial hazard control with NFPA 35, Standard for the Manufacture of Organic Coatings. This standard’s requirements address facilities that manufacture organic chemical-based coatings, such as paints and inks for automotive, industrial, institutional, household, marine, printing, transportation, and other applications. The chapters in NFPA 35 address the following:

NFPA 35 is essential for anyone involved with the design, construction, operation, safety, or maintenance of facilities that produce flammable and combustible organic coatings. The 2026 edition features several updates, including:

Table of Contents Chapter 1 Administration1.1 Scope. Chapter 2 Referenced Publications2.1 General. Chapter 3 Definitions3.1 General. Chapter 4 Location of Plants and Buildings4.1 Location. Chapter 5 Building Construction5.1 General Construction. Chapter 6 Process Equipment and Operations6.1 Transfer of Flammable and Combustible Liquids. Chapter 7 Material Storage and Handling7.1 Tank Car and Tank Vehicle Unloading and Loading. Chapter 8 Special Hazards8.1 Nitrocellulose. Chapter 9 Control of Ignition Sources9.1 Ignition Sources. Chapter 10 Management of Fire Hazards10.1 Scope. Chapter 11 Fire Protection11.1 Scope. Chapter 12 Training and Emergency Planning12.1 Basic Training Requirements. Chapter 13 Inspection and Maintenance13.1 General. Annex A Explanatory Material 2026 (9781455932351) 2021 (9781455927340) 2016 (9781455912971) 2011 (NFPA35-11) |