NFPA 67, Guide on Explosion Protection for Gaseous Mixtures in Pipe Systems

Learn how to better reduce explosion hazards in gaseous pipe systems.

The quintessential resource for designing, installing, and operating explosion protection systems for any facility with process piping, vapor recovery system piping, gas venting piping and manifolds, gas piping for water electrolysis and fuel cell systems, flare systems, and more. NFPA 67, Recommended Practice on Explosion Protection for Gaseous Mixtures in Pipe Systems, provides designers, engineers, installers, contractors, and facility managers invaluable support for better ensuring safety with piping systems.

The 2024 edition includes:

- Completely rewritten text

- Change from a guide to a recommended practice to improve ease of use and accessibility

- Recommendations reorganized into different chapters

- Informational material moved to the annexes

Table of Contents:

Chapter 1 Administration

1.1 Scope.

1.2 Purpose.

1.3 Piping Installation and Maintenance.

1.4 Applications.

Chapter 2 Referenced Publications

2.1 General.

2.2 NFPA Publications.

2.3 Other Publications.

2.4 References for Extracts in Recommended Sections.

Chapter 3 Definitions

3.1 General.

3.2 NFPA Official Definitions.

3.3 General Definitions.

Chapter 4 General Detonation Protection Recommendations

4.1 Detonation Protection Methods Based on the Prevention of Combustion.

4.2 Detonation Protection Methods Based on the Prevention or Limitation of Damage.

4.3 Limitations.

4.4 Factors to be Considered.

4.5 Plans.

4.6 System Acceptance.

4.7 Inspection and Maintenance.

Chapter 5 Detonation Prevention and Mitigation

5.1 Detonation Prevention by Prevention of Combustion.

5.2 Preventing Deflagration-to-Detonation Transition.

5.3 Detonation Isolation.

Chapter 6 Detonation Containment

6.1 General.

6.2 Chapman-Jouguet Detonation Properties.

6.3 Detonation Forces on Piping and Piping Supports.

6.4 Reflected Pressure Waves and Deflagration-to-Detonation Transition (DDT).

6.5 Detonation Containment in Pipes.

6.6 Pipe Structural Response to Detonation Loads.

Chapter 7 Applications of Passive Detonation Protection Strategies

7.1 Underground Storage Vessels.

7.2 Aboveground Storage Vessels.

7.3 Protection of Process Units and Tank Farms from Waste Gas Systems (Incinerators, Flares, Thermal Oxidizers).

7.4 Protection Strategy for Carbon Adsorption Units.

7.5 Protection Strategy for Equipment (Blowers, Vacuum Pumps, etc.).

7.6 Selecting Flame Arresters for Actual Process Conditions.

Chapter 8 Management of Change

8.1 Procedures for Management of Change.

Chapter 9 Installation, Inspection, and Maintenance of Piping Explosion Protection Systems

9.1 General.

9.2 Design Parameters and Documentation.

9.3 Installation.

9.4 Inspection.

9.5 Availability of Explosion Protection System Documentation.

9.6 Maintenance.

9.7 Cleaning.

9.8 Procedures After an Explosion Protection System Event.

9.9 Recordkeeping.

9.10 Personnel Safety and Training.

Annex A Explanatory Material

Annex B Examples of Calculations of Suitable Pipe Wall Thickness for Pipe Wall Elastic Response to Stable Detonations

Annex C Fundamentals of Deflagrations

Annex D Principles of Detonations

Annex E Detonation Propagation Across Boundaries

Annex F Informational References

2024 (9781455931156)

2019 (9781455922000)

| Price | $219.95 |

|---|---|

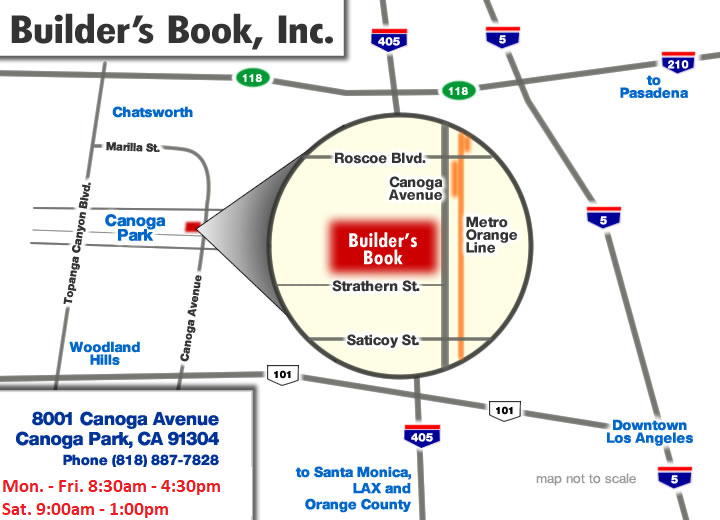

| Customer Service | We're Here To Help! Call us anytime during our customer service hours... Monday through Friday - 8:30 am to 4:30 pm (Pacific) Order Questions:

TOLL FREE, 800-273-7375 (Outside the U.S. call 818-887-7828). Our Address: 8001 Canoga Avenue Canoga Park, CA 91304 US Phone: 800-275-2665 E-mail: sales@buildersbook.com

|

| Description | Learn how to better reduce explosion hazards in gaseous pipe systems. The quintessential resource for designing, installing, and operating explosion protection systems for any facility with process piping, vapor recovery system piping, gas venting piping and manifolds, gas piping for water electrolysis and fuel cell systems, flare systems, and more. NFPA 67, Recommended Practice on Explosion Protection for Gaseous Mixtures in Pipe Systems, provides designers, engineers, installers, contractors, and facility managers invaluable support for better ensuring safety with piping systems. The 2024 edition includes:

Table of Contents: Chapter 1 Administration 1.1 Scope. Chapter 2 Referenced Publications 2.1 General. Chapter 3 Definitions 3.1 General. Chapter 4 General Detonation Protection Recommendations 4.1 Detonation Protection Methods Based on the Prevention of Combustion. Chapter 5 Detonation Prevention and Mitigation 5.1 Detonation Prevention by Prevention of Combustion. Chapter 6 Detonation Containment 6.1 General. Chapter 7 Applications of Passive Detonation Protection Strategies 7.1 Underground Storage Vessels. Chapter 8 Management of Change 8.1 Procedures for Management of Change. Chapter 9 Installation, Inspection, and Maintenance of Piping Explosion Protection Systems 9.1 General. Annex A Explanatory Material 2024 (9781455931156) 2019 (9781455922000) |