NFPA 70B, Standard for Electrical Equipment Maintenance

NFPA 70B, Standard for Electrical Equipment Maintenance, details preventive maintenance for electrical, electronic, and communication systems and equipment—such as industrial plants, institutional and commercial buildings, and large multifamily residential complexes.

When used continually, NFPA 70B helps users develop and carry out an effective Electrical Maintenance Program (EMP) that addresses electrical equipment and systems, which helps prevent equipment failures and employee incidents. All this, while establishing a “condition of maintenance” for equipment that is required to be compliant when assessing risk in accordance with NFPA 70E®, Standard for Electrical Safety in the Workplace®.

The latest updates to NFPA 70B include:

- Improved consistency between chapters, tables, and terminology.

- The potential failure–functional failure (P–F) curve method has been included to determine maximum equipment maintenance intervals.

- A new requirement addresses the need to establish a timeline to avoid delays in conducting necessary equipment repairs or corrections.

- Added details or clarifications to most tasks on inspection and testing tables in equipment chapters.

- A new Chapter 39 on transfer switches has been added.

Table of Contents

Chapter 1 Administration1.1 Scope.

1.2 Purpose.

1.3 Application.

1.4 Equivalency.

1.5 Units of Measurement.

Chapter 2 Referenced Publications2.1 General.

2.2 NFPA Publications.

2.3 Other Publications.

2.4 References for Extracts in Mandatory Sections.

Chapter 3 Definitions3.1 General.

3.2 NFPA Official Definitions.

3.3 General Definitions.

Chapter 4 General4.1 General Requirements.

4.2 Electrical Maintenance Program (EMP).

4.3 Personnel.

4.4 Survey and Analysis.

4.5 Planned Inspections.

4.6 Acceptance Test Report.

4.7 Impact of Additions/Rework to Retrofitting Equipment.

4.8 Equipment Cleaning.

Chapter 5 Personnel Safety5.1 Introduction.

Chapter 6 Single-Line Diagrams and System Studies6.1 Introduction.

6.2 Single-Line Diagrams.

6.3 Short-Circuit Studies.

6.4 Coordination Studies.

6.5 Load-Flow Studies.

6.6 Reliability Studies.

6.7 Incident Energy Analysis (Arc-Flash Study).

6.8 Electrical Maintenance-Related Design.

Chapter 7 Fundamental Tests7.1 Fundamental Tests.

7.2 Bolted Bus Connections, Conductor Terminations, and Conductor Connectors.

7.3 Insulation Resistance Quality.

7.4 Infrared Thermography.

Chapter 8 Field Testing and Test Methods8.1 Introduction.

8.2 Risk Assessment Special Considerations.

8.3 Testing Category Types.

8.4 Test Equipment and Tools.

8.5 Test Record.

8.6 Condition of Maintenance.

Chapter 9 Maintenance Intervals9.1 Scope.

9.2 Equipment Condition Assessment.

9.3 Frequency of Maintenance.

9.4 Scheduling Repairs to Correct Defects.

Chapter 10 Hazardous (Classified) Location Electrical Equipment10.1 Scope.

10.2 General.

10.3 Maintenance Personnel for Hazardous (Classified) Locations.

10.4 Elimination of Hazardous Atmospheres.

10.5 Elimination of Ignition Sources.

10.6 Equipment Reassembly.

10.7 Conduit and Equipment Seals.

10.8 Bolts and Screws.

10.9 Handling of Equipment, Components, and Tools.

10.10 Field Modifications.

Chapter 11 Power and Distribution Transformers11.1 Scope.

11.2 Frequency of Maintenance.

11.3 Periodic Maintenance Procedures.

Chapter 12 Substations and Switchgear12.1 Scope.

12.2 Frequency of Maintenance.

12.3 Periodic Maintenance Procedures.

Chapter 13 Panelboards and Switchboards13.1 Scope.

13.2 Frequency of Maintenance.

13.3 Periodic Maintenance Procedures.

Chapter 14 Busways14.1 Scope.

14.2 Frequency of Maintenance.

14.3 Periodic Maintenance Procedures.

Chapter 15 Circuit Breakers, Low- and Medium-Voltage15.1 Scope.

15.2 Frequency of Maintenance.

15.3 Periodic Maintenance Procedures for Low-Voltage Power Circuit (LVPCB), Molded Case Circuit Breaker (MCCB), and Insulated Case Circuit Breakers (ICCB).

15.4 Periodic Maintenance Procedures for Medium-Voltage Power Circuit Breakers.

Chapter 16 Fuses16.1 Scope.

16.2 Frequency of Maintenance.

16.3 Periodic Maintenance Procedures.

Chapter 17 Switches17.1 Scope.

17.2 Frequency of Maintenance.

17.3 Periodic Maintenance Procedures.

Chapter 18 Power Cables and Conductors18.1 Scope.

18.2 Frequency of Maintenance.

18.3 Periodic Maintenance Procedures.

Chapter 19 Cable Tray19.1 Scope.

19.2 Frequency of Maintenance.

19.3 Periodic Maintenance Procedures.

Chapter 20 Grounding and Bonding20.1 Scope.

20.2 Frequency of Maintenance.

20.3 Periodic Maintenance Procedure.

Chapter 21 Ground-Fault Circuit Interrupters and Ground-Fault Protection of Equipment Systems21.1 Scope.

21.2 Frequency of Maintenance.

21.3 Periodic Maintenance Procedures.

Chapter 22 Lighting22.1 Scope.

22.2 Frequency of Maintenance.

22.3 Periodic Maintenance Procedures.

Chapter 23 Lighting Control Systems (Reserved)

Chapter 24 Wiring Devices24.1 Scope.

24.2 Frequency of Maintenance.

24.3 Periodic Maintenance Procedures.

Chapter 25 Uninterruptible Power Supplies (UPS)25.1 Scope.

25.2 Frequency of Maintenance.

25.3 Periodic Maintenance Procedures.

Chapter 26 Electronic Equipment (Reserved)

Chapter 27 Rotating Equipment27.1 Scope.

27.2 Frequency of Maintenance.

27.3 Periodic Maintenance Procedures.

Chapter 28 Motor Control Equipment28.1 Scope.

28.2 Frequency of Maintenance.

28.3 Periodic Maintenance Procedures.

Chapter 29 Portable Electrical Tools and Equipment29.1 Scope.

29.2 Frequency of Maintenance.

29.3 Periodic Maintenance Procedures.

Chapter 30 Photovoltaic Systems30.1 Scope.

30.2 Frequency of Maintenance.

30.3 Periodic Maintenance Procedures.

30.4 Documentation and Labeling.

Chapter 31 Wind Power Electric Systems and Associated Equipment31.1 Scope.

31.2 Frequency of Maintenance.

31.3 Periodic Maintenance Procedures.

Chapter 32 Battery Energy Storage Systems32.1 Scope.

32.2 Frequency of Maintenance.

32.3 Periodic Maintenance Procedures.

32.4 Documentation.

Chapter 33 Electric Vehicle Power Transfer Systems and Associated Equipment33.1 Scope.

33.2 Frequency of Maintenance.

33.3 Periodic Maintenance Procedures.

33.4 Documentation.

Chapter 34 Public Pools, Fountains, and Similar Installations34.1 Scope.

34.2 Frequency of Maintenance.

34.3 Periodic Maintenance Procedures.

Chapter 35 Protective Relays35.1 Scope.

35.2 Frequency of Maintenance.

35.3 Periodic Maintenance Procedures.

Chapter 36 Stationary Standby Batteries36.1 Scope.

36.2 Frequency of Maintenance.

36.3 Periodic Maintenance Procedures.

36.4 Documentation.

Chapter 37 Instrument Transformers (Reserved)

Chapter 38 Control Power Transformers (Reserved)

Chapter 39 Transfer Switch Equipment39.1 Scope.

39.2 Frequency of Maintenance.

39.3 Periodic Maintenance Procedures.

Annex A Explanatory Material

Annex B Suggestions for Inclusion in a Walk-Through Inspection Checklist

Annex C Symbols

Annex D Diagrams

Annex E Forms

Annex F NEMA Configurations

Annex G Primary Contact Matrix

Annex H Equipment Storage and Maintenance During Construction

Annex I Reliability Centered Maintenance

Annex J Power Quality

Annex K Electrical Disaster Recovery

Annex L Case Histories

2026 (9781455932498)

2023 (9781455929719)

2019 (9781455922031)

2016 (9781455913022)

2013 (NFPA70B-13)

2010 (NFPA70B-10)

| Price | $219.95 |

|---|---|

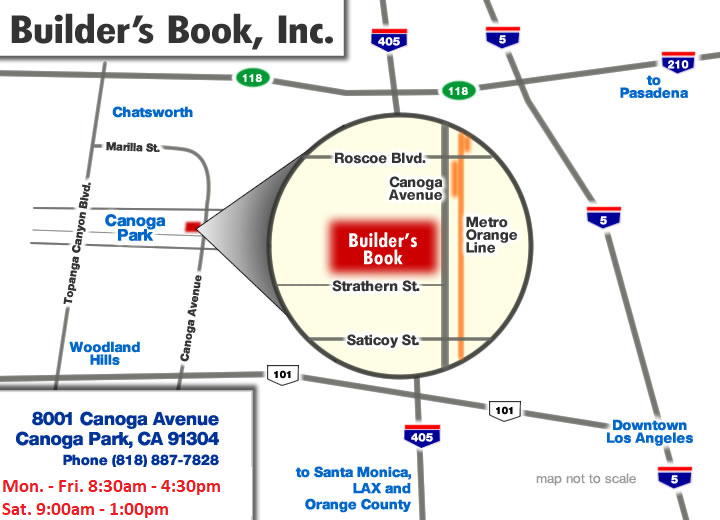

| Customer Service | We're Here To Help! Call us anytime during our customer service hours... Monday through Friday - 8:30 am to 4:30 pm (Pacific) Order Questions:

TOLL FREE, 800-273-7375 (Outside the U.S. call 818-887-7828). Our Address: 8001 Canoga Avenue Canoga Park, CA 91304 US Phone: 800-275-2665 E-mail: sales@buildersbook.com

|

| Description | NFPA 70B, Standard for Electrical Equipment Maintenance, details preventive maintenance for electrical, electronic, and communication systems and equipment—such as industrial plants, institutional and commercial buildings, and large multifamily residential complexes. When used continually, NFPA 70B helps users develop and carry out an effective Electrical Maintenance Program (EMP) that addresses electrical equipment and systems, which helps prevent equipment failures and employee incidents. All this, while establishing a “condition of maintenance” for equipment that is required to be compliant when assessing risk in accordance with NFPA 70E®, Standard for Electrical Safety in the Workplace®. The latest updates to NFPA 70B include:

Table of Contents Chapter 1 Administration1.1 Scope. Chapter 2 Referenced Publications2.1 General. Chapter 3 Definitions3.1 General. Chapter 4 General4.1 General Requirements. Chapter 5 Personnel Safety5.1 Introduction. Chapter 6 Single-Line Diagrams and System Studies6.1 Introduction. Chapter 7 Fundamental Tests7.1 Fundamental Tests. Chapter 8 Field Testing and Test Methods8.1 Introduction. Chapter 9 Maintenance Intervals9.1 Scope. Chapter 10 Hazardous (Classified) Location Electrical Equipment10.1 Scope. Chapter 11 Power and Distribution Transformers11.1 Scope. Chapter 12 Substations and Switchgear12.1 Scope. Chapter 13 Panelboards and Switchboards13.1 Scope. Chapter 14 Busways14.1 Scope. Chapter 15 Circuit Breakers, Low- and Medium-Voltage15.1 Scope. Chapter 16 Fuses16.1 Scope. Chapter 17 Switches17.1 Scope. Chapter 18 Power Cables and Conductors18.1 Scope. Chapter 19 Cable Tray19.1 Scope. Chapter 20 Grounding and Bonding20.1 Scope. Chapter 21 Ground-Fault Circuit Interrupters and Ground-Fault Protection of Equipment Systems21.1 Scope. Chapter 22 Lighting22.1 Scope. Chapter 23 Lighting Control Systems (Reserved) Chapter 24 Wiring Devices24.1 Scope. Chapter 25 Uninterruptible Power Supplies (UPS)25.1 Scope. Chapter 26 Electronic Equipment (Reserved) Chapter 27 Rotating Equipment27.1 Scope. Chapter 28 Motor Control Equipment28.1 Scope. Chapter 29 Portable Electrical Tools and Equipment29.1 Scope. Chapter 30 Photovoltaic Systems30.1 Scope. Chapter 31 Wind Power Electric Systems and Associated Equipment31.1 Scope. Chapter 32 Battery Energy Storage Systems32.1 Scope. Chapter 33 Electric Vehicle Power Transfer Systems and Associated Equipment33.1 Scope. Chapter 34 Public Pools, Fountains, and Similar Installations34.1 Scope. Chapter 35 Protective Relays35.1 Scope. Chapter 36 Stationary Standby Batteries36.1 Scope. Chapter 37 Instrument Transformers (Reserved) Chapter 38 Control Power Transformers (Reserved) Chapter 39 Transfer Switch Equipment39.1 Scope. Annex A Explanatory Material 2026 (9781455932498) 2023 (9781455929719) 2019 (9781455922031) 2016 (9781455913022) 2013 (NFPA70B-13) 2010 (NFPA70B-10) |